High-Strength GRP SMC Water Tanks for Residential, Commercial & Industrial Use

GRP SMC Tanks are Glass Reinforced Plastic (GRP) Sheet Moulding Compound (SMC) Tanks. They are widely used for storing water and other liquids due to their high strength, durability, and resistance to corrosion. These tanks are manufactured using a process that combines glass fibres with polyester resin to form a strong, molded product. This makes them ideal for various applications, including water storage, chemical storage, and wastewater treatment. Their lightweight nature and ease of installation also make them a popular choice in residential, commercial, and industrial settings.

WHAT IS SMC?

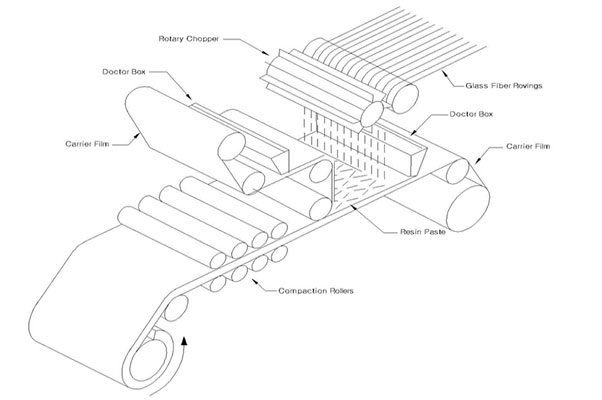

A thermosetting compound is created by blending an unsaturated polyester resin with additives such as a release agent, diluent, hardener, polymerization inhibitor, thermoplastic, pigment, and thickener. To maintain the desired viscosity, a water-retaining agent and dispersant are incorporated during mixing. The mixture is then aged to achieve the target viscosity. Glass fibers, spaced 1 inch apart, are impregnated with this compound to form SHEET in a semi-solid state. The material is subsequently shaped and solidified through compression molding using a large hydraulic press under high temperature and pressure.