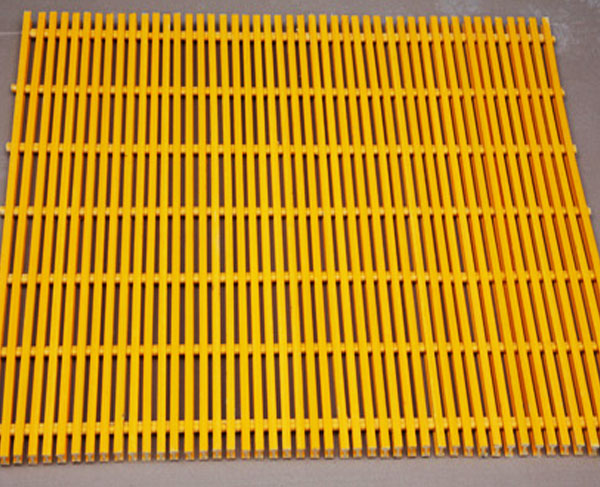

High-Performance FRP Pultruded Gratings for Industrial Applications

FRP Pultruded Gratings are crafted using a continuous pultrusion process that ensures high strength, durability, and consistent quality. These gratings are known for their exceptional load-bearing capabilities and resistance to corrosive environments, making them ideal for industrial applications. With various resin options and surface finishes available, FRP Pultruded Gratings provide versatile and reliable solutions for areas requiring enhanced safety and performance.

Key Characteristics of FRP Pultruded Gratings

- High Strength: Exceptional load-bearing capacity.

- Corrosion Resistant: Ideal for harsh chemical environments.

- Durable: Long-lasting with minimal wear and tear.

- Non-Conductive: Safe for electrical and telecommunications use.

- Fire Retardant: Available in fire-resistant grades.

- Lightweight: Easier to install and transport.

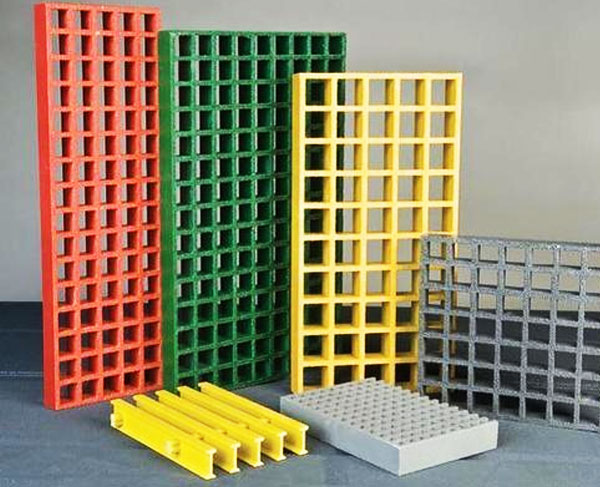

- Customizable: Available in various sizes and surface finishes.

- Low Maintenance: Requires minimal upkeep, reducing overall costs.

Applications

- Walkways

- Trench Covers

- Staircase

- Foot Bridges

- Fencing

- Step Treads

- Platforms

- Earth Pit Covers and More

Types of Pultruded Gratings

- I-Shaped Bars

- T-Shaped Bars

- High Load Bars

Sectors Served by FRP Pultruded Gratings

- Chemical Processing Plants

- Oil and Gas Industry

- Water and Wastewater Treatment Plants

- Marine and Offshore Platforms

- Power Plants

- Transportation and Infrastructure

- Food and Beverage Industry

- Pharmaceuticals