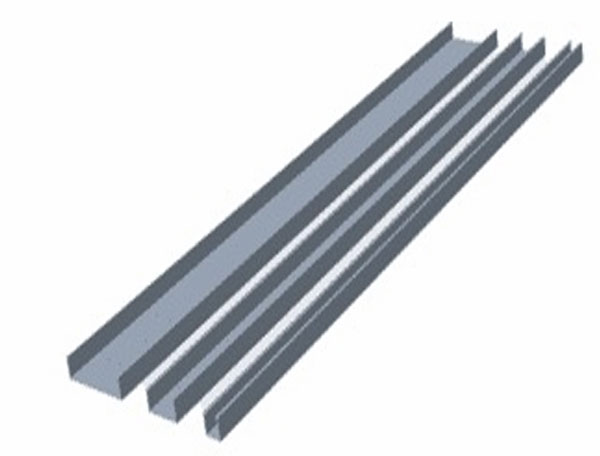

FRP GRP Ladder Cable Trays

FRP GRP Perforated Cable Trays are designed with a solid bottom featuring ventilation holes and slots to enable proper air circulation and secure cable tie placement. These trays provide an ideal balance of protection and airflow for cable management in electrical systems. Ventilated bottoms include 8mm diameter perforations and strategically placed slots to support cable tie installation.

These trays are available in widths ranging from 50mm to 600mm, with heights up to 100mm and thickness options of 3mm, 4mm, 5mm, and 6mm. FRP Channel trays are typically supplied in 3000mm standard lengths, with pre-punched splice holes at both ends to facilitate easy joining with splice plates and hardware.

Key Features of FRP GRP Perforated Cable Trays

- Ventilated bottom with 8mm perforations for airflow

- Slots provided for secure cable tie usage

- Available in multiple widths (50mm to 600mm)

- Height options up to 100mm

- Thickness available: 3mm, 4mm, 5mm, and 6mm

- Standard length: 3000mm with pre-punched splice holes

- Corrosion resistant and fire retardant material

- Ideal for electrical and telecom installations